Determinants of Food Safety Level in Fruit and Vegetable Wholesalers’ Supply Chain: Evidence from Spain and France

Abstract

:1. Introduction

2. Background: Agri-Food Safety in Long Supply Chains

3. Hypotheses of Analysis

4. Methodology

4.1. Data

4.2. Variables and Model Description

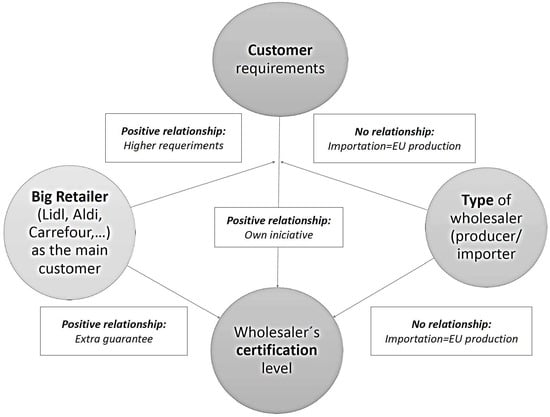

- CUST: The degree of customer requirements measured by a 1–5 Likert scale where 1 is low customer demand and 5 is maximum requirement. More specifically, this variable represents the perception of wholesalers regarding the pressure exerted on them by their main customers in terms of food quality and safety [15,58]. The intensity of this variable depends on a vast range of factors, such as the importance that customers place on certification, in-house safety control (without third parties), the level of complaints, and even the degree of trust between wholesalers and customers [42].

- DIST: Represents the type of customer or distributor. It is the percentage of sales carried out through big retailers over total sales. According to [58], there is a direct relationship between a wholesaler’s level of certification and the fact that their main customer is a big retailer.

- TYPE: Indicates the type of supplier, that is, whether the wholesaler is primarily an importer (of F&V from third countries to the EU) or is mainly supplied by their own production, cooperatives, or European farmers [56]. This is a dummy variable that takes a value of 1 when the majority of the wholesaler’s produce comes from importation, and 0 in all other cases.

- AGE: The number of years that the wholesaler has been operating as an indicator of experience and years in the business.

- TURN: The annual turnover of the wholesaler (in thousands of euros). It is an indicator of company size. In the literature, the size of a company produces varied results in relation to efforts made to implement food safety. Some studies [67,68] indicate that the largest companies are those which make the greatest efforts in this regard, while others [58] suggest the opposite.

- EMP: The number of employees, which is also indicative of the size of the wholesaler.

- DIV: The degree of specialization, measured by the number of products the wholesaler deals in. The diversification of a product portfolio might prevent a company from receiving certification.

5. Results

6. Discussions

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jacxsens, L.; Boxstael, S.V.; Nanyunja, J.; Jordaan, D.; Luning, P.; Uyttendaele, M. Opinions on Fresh Produce Food Safety and Quality Standards by Fresh Produce Supply Chain Experts from the Global South and North. J. Food Prot. 2015, 78, 1914–1924. [Google Scholar] [CrossRef] [PubMed]

- Kirezieva, K.; Jacxsens, L.; Hagelaar, G.J.L.F.; van Boekel, M.A.J.S.; Uyttendaele, M.; Luning, P.A. Exploring the influence of context on food safety management: Case studies of leafy greens production in Europe. Food Policy 2015, 51, 158–170. [Google Scholar] [CrossRef]

- Willems, S.; Roth, E.; van Roekel, J. Changing European Public and Private Food Safety Requirements: Challenges for Developing Country Fresh Produce and Fish Exporters; The World Bank: Washington, DC, USA, 2005. [Google Scholar]

- Pérez-Mesa, J.C.; Galdeano-Gómez, E. Collaborative firms managing perishable products in a complex supply network: An empirical analysis of performance. Supply Chain Manag. Int. J. 2015, 20, 128–138. [Google Scholar] [CrossRef]

- Hammoudi, A.; Hoffmann, R.; Surry, Y. Food safety standards and agri-food supply chains: An introductory overview. Eur. Rev. Agric. Econ. 2009, 36, 469–478. [Google Scholar] [CrossRef]

- Lemeilleur, S. Smallholder Compliance with Private Standard Certification: The Case of GlobalGAP Adoption by Mango Producers in Peru. Int. Food Agribus. Manag. Rev. 2013, 16, 159–180. [Google Scholar]

- Zhou, J.; Li, K.; Liang, Q. Food safety controls in different governance structures in China’s vegetable and fruit industry. J. Integr. Agric. 2015, 14, 2189–2202. [Google Scholar] [CrossRef]

- Johannessen, G.S.; Cudjoe, K.S. Regulatory Issues in Europe Regarding Fresh Fruit and Vegetable Safety; Section for Food Bacteriology and GMO, National Veterinary Institute: Oslo, Norway, 2009.

- Fulponi, L.; Giraud-Héraud, E.; Hammoudi, H.; Valceschini, E. Sécurité Sanitaire et Normes Collectives de Distributeurs: Impact sur les Filières et L’offre Alimentaire; INRA-Sciences Sociales, INRA Department of Economics: Paris, France, 2006. [Google Scholar]

- Losasso, C.; Cibin, V.; Cappa, V.; Roccato, A.; Vanzo, A.; Andrighetto, I.; Ricci, A. Food safety and nutrition: Improving consumer behaviour. Food Control 2012, 26, 252–257. [Google Scholar] [CrossRef]

- Henson, S.; Humphrey, J. Les Impacts des Normes Privées de Sécurité Sanitaire des Aliments sur la Chaîne Alimentaire et sur les Processus Publics de Normalisation; Commission of Codex Alimentarius, FAO: Rome, Italy; Commission of Codex Alimentarius, OMS: Geneve, Switzerland, 2009. [Google Scholar]

- Halkier, B.; Holm., L. Shifting responsibilities for food safety in Europe: An introduction. Appetite 2006, 47, 127–133. [Google Scholar] [CrossRef] [PubMed]

- Akkerman, R.; Farahani, P.; Grunow, M. Quality, safety and sustainability in food distribution: A review of quantitative operations management approaches and challenges. OR Spectr. 2010, 32, 863. [Google Scholar] [CrossRef]

- Traill, W.; Koenig, A. Economic assessment of food safety standards: Costs and benefits of alternative approaches. Food Control 2010, 21, 1611–1619. [Google Scholar] [CrossRef]

- Mensah, L.D.; Julien, D. Implementation of food safety management systems in the UK. Food Control 2011, 28, 1216–1225. [Google Scholar] [CrossRef] [Green Version]

- Henson, S.; Reardon, T. Private agri-food standards: Implications for food policy and the agri-food system. Food Policy 2005, 30, 241–252. [Google Scholar] [CrossRef]

- Serrano-Arcos, M.; Pérez-Mesa, J.C.; Sánchez-Fernández, R. Product-country image and crises in the Spanish horticultural sector: Classification and impact on the market. Agric. Resour. Econ. 2018, 18, 111–133. [Google Scholar] [CrossRef]

- Codron, J.M.; Adanacioğlu, H.; Aubert, M.; Bouhsina, Z.; Ait El Mekki, A.; Rousset, S.; Tozanli, S.; Yercan, M. The role of market forces and food safety institutions in the adoption of sustainable farming practices: The case of the fresh tomato export sector in Morocco and Turkey. Food Policy 2014, 49, 268–280. [Google Scholar] [CrossRef]

- Kirezieva, K.; Luning, P.A.; Jacxsens, L.; Uyttendaele, M. Status of food safety management activities in fresh produce companies in the European Union and beyond. Acta Horticulturae 2015, 1103, 167–174. [Google Scholar] [CrossRef]

- Nanyunja, J.; Jacxsens, L.; Kirezieva, K.; Kaaya, A.N.; Uyttendaele, M.; Luning, P.A. Assessing the Status of Food Safety Management Systems for Fresh Produce Production in East Africa: Evidence from Certified Green Bean Farms in Kenya and Noncertified Hot Pepper Farms in Uganda. J. Food Prot. 2015, 78, 1081–1089. [Google Scholar] [CrossRef] [PubMed]

- Eurostat. International Trade in Goods. 2016. Available online: https://ec.europa.eu/eurostat/web/international-trade-in-goods/data/database (accessed on 4 September 2017).

- Havinga, T. Private Regulation of Food Safety by Supermarkets. Law Policy 2006, 28, 515–533. [Google Scholar] [CrossRef]

- Grazia, C.; Hammoudi, A. Las cadenas de valor globales y la heterogeneidad en los estándares de seguridad alimentaria: Una panorámica sobre las principales cuestiones económicas. Cuad. de Estud. Agroaliment. 2012, 1, 47–68. [Google Scholar]

- Houghton, J.R.; Rowe, G.; Frewer, L.J.; Van Kleef, E.; Chryssochoidis, G.; Kehagia, O.; Korzen-Bohr, S.; Lassen, J.; Pfenning, U.; Strada, A. The quality of food risk management in Europe: Perspectives and priorities. Food Policy 2008, 33, 13–26. [Google Scholar] [CrossRef]

- Papadopoulos, A.; Sargeant, J.M.; Majowicz, S.E.; Sheldrick, B.; McKeen, C.; Wilson, J.; Dewey, C.E. Enhancing public trust in the food safety regulatory system. Health Policy 2012, 107, 98–103. [Google Scholar] [CrossRef] [PubMed]

- De Jonge, J.; van Trijp, J.C.M.; van der Lans, I.A.; Renes, R.J.; Frewer, L.J. How trust in institutions and organizations builds general consumer confidence in the safety of food: A decomposition of effects. Appetite 2008, 51, 311–317. [Google Scholar] [CrossRef] [PubMed]

- Trienekens, J.; Zuurbier, P. Quality and safety standards in the food industry, developments and challenges. Int. J. Prod. Econ. 2008, 113, 107. [Google Scholar] [CrossRef]

- Bailey, A.P.; Garforth, C. An industry viewpoint on the role of farm assurance in delivering food safety to the consumer: The case of the dairy sector of England and Wales. Food Policy 2014, 45, 14–24. [Google Scholar] [CrossRef]

- Ziggers, G.W.; Trienekens, J. Quality assurance in food and agribusiness supply chains: Developing successful partnerships. Int. J. Prod. Econ. 1999, 60–61, 271–279. [Google Scholar] [CrossRef]

- Siddh, M.M.; Soni, G.; Jain, R.; Sharma, M.K.; Yadav, V. Agri-fresh food supply chain quality (AFSCQ): A literature review. Ind. Manag. Data Syst. 2017, 117, 2015–2044. [Google Scholar] [CrossRef]

- Hou, M.A.; Grazia, C.; Malorgio, G. Food safety standards and international supply chain organization: A case study of the Moroccan fruit and vegetable exports. Food Control 2015, 55, 190–199. [Google Scholar] [CrossRef]

- Khatri, Y.; Collins, R. Impact and status of HACPP in the Australian meat industry. Br. Food J. 2007, 109, 343–354. [Google Scholar] [CrossRef]

- Wilcock, A.; Ball, B.; Fajumo, A. Effective implementation of food safety initiatives: managers’, food safety coordinators’ and production workers’ perspectives. Food Control 2011, 22, 27–32. [Google Scholar] [CrossRef]

- Jin, S.; Zhou, J.; Ye, J. Adoption of HACCP system in the Chinese food industry. Food Control 2008, 19, 823–828. [Google Scholar] [CrossRef]

- Fotopoulos, C.V.; Kafetzopoulos, D.P.; Psomas, E.L. Assessing the critical factors and their impact on the effective implementation of a food safety management system. Int. J. Qual. Reliab. Manag. 2009, 26, 894–910. [Google Scholar] [CrossRef]

- Mamalis, S.; Kafetzopoulos, P.; Aggelopoulos, S. The new food safety standard ISO 22000. Assessment, comparison and correlation with HACCP and ISO 9000:2000: The practical implementation in victual business. In Proceedings of the 13th EAAE Seminar “A Resilient European Food Industry and Food Chain in a Challenging world”, Chania, Crete, Greece, 3–6 September 2009. [Google Scholar]

- Escanciano, C.; Santos-Vijande, M.L. Reasons and constraints to implementing an ISO 22000 food safety management system: Evidence from Spain. Food Control 2014, 40, 50–57. [Google Scholar] [CrossRef]

- Maldonado-Simán, E.; Martinez-Hernandez, P.A.; Garcia-Muñiz, J.G.; Cadena-Meneses, J.C. Factors associated with the adoption of food safety controls by the Mexican meat industry. Comput. Comput. Technol. Agric. 2009, 3, 1739–1746. [Google Scholar]

- Henson, S.; Holt, G. Exploring incentives of food safety controls: HACCP implementation in the UK dairy sector. Rev. Agric. Econ. 2000, 22, 407–420. [Google Scholar] [CrossRef]

- Herath, D.; Henson, S. Does Canada need mandatory HACCP? Evidence from the Ontario food processing sector. Can. J. Agric. Econ. 2006, 54, 443–459. [Google Scholar] [CrossRef]

- Violaris, Y.; Bridges, O.; Bridges, J. Small business-big risks: Current status and future direction of APPCC in Cyprus. Food Control 2007, 19, 439–448. [Google Scholar] [CrossRef]

- Fotopoulos, C.V.; Kafetzopoulos, D.P.; Gotzamani, K. Critical factors for effective implementation of the HACCP system: A Pareto analysis. Br. Food J. 2011, 113, 578–597. [Google Scholar] [CrossRef]

- Fares, M.; Rouvière, E. The implementation mechanisms of voluntary food safety systems. Food Policy 2010, 35, 412–418. [Google Scholar] [CrossRef]

- Saad, M.; See, T.P.; Mohamed Adil, M.A.; Moginon, D.F. The Impact of Food Safety Practices on Organizational Performance. In Current Issues in Hospitality and Tourism Research and Innovations—Proceedings of the International Hospitality and Tourism Conference, Kuala Lumpur, Malaysia, 3–5 September 2012; Taylor & Francis Group: London, England; pp. 201–203.

- Kleinwechter, U.; Grethe, H. The Adoption of the Eurepgap Standard by Mango Exporters in Piura, Peru. In Proceedings of the Annual Meeting of International Association of Agricultural Economists, Queensland, Australia, 12–18 August 2006. [Google Scholar]

- Konefal, J.; Mascarenhas, M.; Hatanaka, M. Governance in the Global Agro-food System: Backlighting the Role of Transnational Supermarket Chains. Agric. Hum. Values 2005, 22, 291–302. [Google Scholar] [CrossRef]

- Lee, J.; Gereffi, G.; Beauvais, J. Global Value Chains and Agrifood Standards: Challenges and Possibilities for Smallholders in Developing Countries. Proc. Natl. Acad. Sci. USA 2010, 109, 12326–12331. [Google Scholar] [CrossRef] [PubMed]

- Giraud-Héraud, E.; Hammoudi, A.; Hoffmann, R.; Soler, L.G. Joint Private Safety Standards and Vertical Relationships in Food Retailing. J. Econ. Manag. Strategy 2012, 21, 179–212. [Google Scholar] [CrossRef]

- Rouvière, E.; Latouche, K. Impact of liability rules on modes of coordination for food safety in supply chains. Eur. J. Law Econ. 2014, 37, 111–130. [Google Scholar] [CrossRef] [Green Version]

- Okello, J.J.; Narrod, C.A.; Roy, D. Export standards, market institutions and smallholder farmer exclusion from fresh export vegetable high value chains: Experiences from Ethiopia, Kenya, and Zambia. J. Agric. Sci. 2011, 3, 188–195. [Google Scholar] [CrossRef]

- Mercasa. La Alimentación en España 2016. Available online: http://www.mercasa.es/nosotros/alimentacion_en_espana (accessed on 18 November 2017).

- Review FyH. Block Mayoristas 2015. Available online: https://www.fyh.es/publicaciones.aspx (accessed on 2 November 2017).

- Behr, H.C. Fresh Vegetables for Tomorrow’s Consumers—A German Perspective; European Vegetable Strategies: Brussels, Belgium, 2014. [Google Scholar]

- Bernard, A.; Jensen, J.; Schott, P. Importers, exporters and multi-nationals: A portrait of firms in the U.S. that trade goods. NBER Work. Pap. 2005, 11404. [Google Scholar] [CrossRef]

- Bernard, A.; Grazzi, M.; Tomasi, C. Intermediaries in International Trade: Direct vs. indirect modes of exports. Lab. Econ. Manag. Work. Pap. Ser. 2010, 45. [Google Scholar] [CrossRef]

- Latouche, K.; Rouvière, E. Brokers vs. Retailers: Evidence from the French Imports Industry of Fresh Produc. In Proceedings of the International Congress from European Association of Agricultural Economics, Zurich, Switzerland, 30 August–2 September 2011. [Google Scholar]

- Belleáamme, P.; Peitz, M. Industrial Organization: Markets and Strategies; University Press: Cambridge, UK, 2010. [Google Scholar]

- Rouvière, E.; Soubeyran, R.; Bignebat, C. Heterogenous efforts in voluntary programmes on food safety. Eur. Rev. Agric. Econ. 2010, 37, 479–499. [Google Scholar] [CrossRef] [Green Version]

- Rouvière, E. Small is beautiful: Firm size, prevention and food safety. Food Policy 2016, 63, 12–22. [Google Scholar] [CrossRef]

- García, M.; Poole, N. The development of private fresh produce safety standards: Implications for developing Mediterranean exporting countries. Food Policy 2004, 29, 229–255. [Google Scholar] [CrossRef]

- Li, B.; Jin, T.; Haiheng, T.; Yu, A.; Shunlong, G. Costs and benefits of implementing and operating HACCP in the Chinese Food Enterprises. In Proceedings of the 5th International Conference on Bioinformatics and Biomedical Engineering, Wuhan, China, 10–12 May 2011. [Google Scholar]

- Karipidis, P.; Athanassiadis, K.; Aggelopoulos, S.; Giompliakis, E. Factors affecting the adoption of quality assurance systems in small food enterprises. Food Control 2009, 20, 93–98. [Google Scholar] [CrossRef]

- Macheka, L.; Manditsera, F.A.; Ngadze, R.T.; Mubaiwa, J.; Nyanga, L.K. Barriers, benefits and motivation factors for the implementation of food safety management system in the food sector in Harare Province, Zimbabwe. Food Control 2013, 34, 126–131. [Google Scholar] [CrossRef]

- Baert, K.; Van Huffel, X.; Jacxsens, L.; Berkvens, D.; Diricks, H.; Huyghebaert, A.; Uyttendaele, M. Measuring the perceived pressure and stakeholders’ response that may impact the status of the safety of the food chain in Belgium. Food Res. Int. 2012, 48, 257–264. [Google Scholar] [CrossRef]

- Ramnauth, M.; Driver, F.; Vial, P.B. Food safety management in the fish industry in Mauritius: Knowledge, attitude and perception. Br. Food J. 2008, 110, 989–1005. [Google Scholar] [CrossRef]

- Balsevich, F.; Berdegué, J.; Flores, L.; Mainville, D.; Reardon, T. Supermarkets and produce quality and safety standards in Latin America. Am. J. Agric. Econ. 2003, 85, 1147–1154. [Google Scholar] [CrossRef]

- Grolleau, G.; Mzoughi, N.; Thomas, A. What drives agrifood firms to register for an Environmental Management System? Eur. Rev. Agric. Econ. 2006, 34, 233–255. [Google Scholar] [CrossRef]

- Galliano, D.; Orozco, L. The determinants of electronic traceability adoption: A firm-level analysis of French agribusiness. Agribusiness 2011, 27, 379–397. [Google Scholar] [CrossRef] [Green Version]

- Cai, R.; Ma, W.; Su, Y. Effects of member size and selective incentives of agricultural cooperatives on product quality. Br. Food J. 2016, 118, 858–870. [Google Scholar] [CrossRef]

- Aiken, L.S.; West, S.G. Multiple Regression: Testing and Interpreting Interactions; Sage: London, UK, 1991. [Google Scholar]

| Consumer Direct Purchase 1 | Spain | France | Germany |

|---|---|---|---|

| Super-Hyper-Discount | 43% (20%) | 73% (35%) | 86% (25%) |

| Traditional Shops | 40% (95%) | 20% (90%) | 12% (92%) |

| Others (Self-consumption, street markets) | 17% (63%) | 7% (83%) | 2% (90%) |

| Total | 100% (57%) | 100% (49%) | 100% (34%) |

| PROM | DESV | MAX | MIN | CERT | CUST | DIST | TYPE | TURN | AGE | EMP | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| CERT | 42.30 | 34.34 | 100.00 | 0.00 | 1 | ||||||

| CUST | 2.43 | 1.45 | 5.00 | 1.00 | 0.160 | 1 | |||||

| DIST | 28.89 | 27.42 | 90.00 | 0.00 | −0.102 | 0.181 | 1 | ||||

| TYPE | 0.26 | 0.44 | 1.00 | 0.00 | 0.210 | 0.426 | 0.215 | 1 | |||

| TURN | 40,738 | 83,498 | 755,851 | 180.00 | 0.017 | 0.307 | 0.119 | 0.170 | 1 | ||

| AGE | 29.05 | 17.43 | 51.00 | 3.00 | −0.194 | 0.074 | 0.061 | 0.043 | 0.372 | 1 | |

| EMP | 25.38 | 42.19 | 301.00 | 1.00 | −0.061 | 0.130 | 0.049 | −0.029 | 0.686 | 0.395 | 1 |

| DIV | 8.46 | 6.85 | 17.00 | 1.00 | 0.102 | 0.098 | 0.191 | 0.038 | 0.321 | 0.033 | 0.271 |

| Variable | Model 1 | Model 2 | Model 3 |

|---|---|---|---|

| Constant | −0.373 | −0.424 | −0.321 |

| CUST (Hyp. 1) | 0.465 ** | 0.457 ** | 0.387 ** |

| DIST (Hyp. 2) | 0.268 * | 0.305 * | |

| TYPE (Hyp. 4) | −0.145 | −0.237 | |

| DIST × CUST (Hyp. 3) | 0.109 * | ||

| TYPE × CUST (Hyp. 5) | 0.018 | ||

| AGE | −0.022 ** | −0.030 ** | −0.012 * |

| TURN | 0.060 | 0.063 | 0.018 |

| EMP | 0.024 | 0.015 | 0.005 |

| DIV | 0.002 | −0.008 | −0.011 |

| R2 | 0.338 | 0.453 | 0.618 |

| Variation R2 | 0.115 | 0.165 | 0.115 |

| Adjusted R2 | 0.295 | 0.434 | 0.455 |

| D-W | 1.919 | 1.615 | 1.558 |

| χ2 Farrar-Glauber | 11,721 | 16,009 | 19,565 |

| White Test | 6382 | 9482 | 7410 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernández-Rubio, J.; Pérez-Mesa, J.C.; Piedra-Muñoz, L.; Galdeano-Gómez, E. Determinants of Food Safety Level in Fruit and Vegetable Wholesalers’ Supply Chain: Evidence from Spain and France. Int. J. Environ. Res. Public Health 2018, 15, 2246. https://0-doi-org.brum.beds.ac.uk/10.3390/ijerph15102246

Hernández-Rubio J, Pérez-Mesa JC, Piedra-Muñoz L, Galdeano-Gómez E. Determinants of Food Safety Level in Fruit and Vegetable Wholesalers’ Supply Chain: Evidence from Spain and France. International Journal of Environmental Research and Public Health. 2018; 15(10):2246. https://0-doi-org.brum.beds.ac.uk/10.3390/ijerph15102246

Chicago/Turabian StyleHernández-Rubio, Jesús, Juan C. Pérez-Mesa, Laura Piedra-Muñoz, and Emilio Galdeano-Gómez. 2018. "Determinants of Food Safety Level in Fruit and Vegetable Wholesalers’ Supply Chain: Evidence from Spain and France" International Journal of Environmental Research and Public Health 15, no. 10: 2246. https://0-doi-org.brum.beds.ac.uk/10.3390/ijerph15102246