Brief Overview on Bio-Based Adhesives and Sealants

Abstract

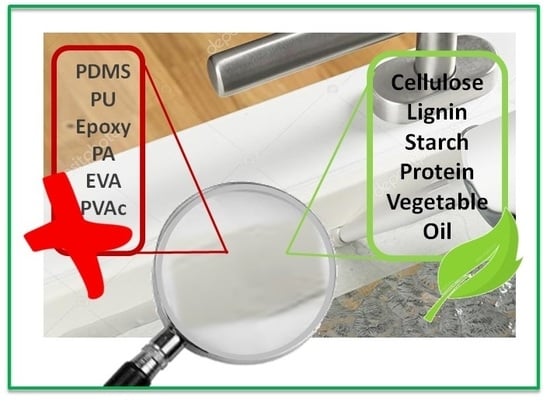

:1. Background

2. Organosilicon Based Adhesives and Sealants

3. Fundamentals of Adhesion

4. New Generation of Adhesives and Sealants

5. Cellulose-Based Adhesives and Sealants

6. Starch Based Adhesives and Sealants

7. Lignin Based Adhesives and Sealants

8. Other Systems: Vegetable Oils and Protein Based Silanes

9. Concluding Remarks

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Segura, D.M.; Nurse, A.D.; McCourt, A.; Phelps, R.; Segura, A. Chapter 3 Chemistry of polyurethane adhesives and sealants. In Handbook of Adhesives and Sealants; Cognard, P., Ed.; Elsevier Science Ltd.: New York, NY, USA, 2005; Volume 1, pp. 101–162. [Google Scholar]

- He, Z. (Ed.) Bio-based Wood Adhesives: Preparation, Characterization, and Testing; CRC Press: Boca Raton, FL, USA, 2017; pp. 1–356. [Google Scholar]

- Petric, M. Influence of Silicon-Containing Compounds on Adhesives for and Adhesion to Wood and Lignocellulosic Materials: A Critical Review. Rev. Adhes. Adhes. 2018, 6, 26–81. [Google Scholar] [CrossRef]

- Pizzi, A.; Mittal, K.L. (Eds.) Wood Adhesives; CRC Press: Boca Raton, FL, USA, 2011; pp. 1–451. [Google Scholar]

- Ogliani, E.; Yu, L.; Mazurek, P.; Skov, A.L. Designing reliable silicone elastomers for high-temperature applications. Polym. Degrad. Stab. 2018, 157, 175–180. [Google Scholar] [CrossRef]

- Kim, H.J.; Lim, D.H.; Hwang, H.D.; Lee, B.H. Composition of Adhesives. In Handbook of Adhesion Technology; da Silva, L.F.M., Öchsner, A., Adams, R.D., Eds.; Springer Berlin Heidelberg: Berlin/Heidelberg, Germany, 2011; pp. 291–314. [Google Scholar]

- Guillaume, S.M. Advances in the synthesis of silyl-modified polymers (SMPs). Polym. Chem. 2018, 9, 1911–1926. [Google Scholar] [CrossRef]

- Research, Z.M. Global Silane Modified Polymer Market 2019—Henkel Ltd., The Dow Chemical Company, Evonik, Kaneka Americas Holding, Inc. Available online: https://economicsaffairs.com/global-silane-modified-polymer-market-2019-henkel-ltd-the-dow-chemical-company-evonik-kaneka-americas-holding-inc/6176/ (accessed on 2 February 2019).

- Darracq, G.; Couvert, A.; Couriol, C.; Amrane, A.; Thomas, D.; Dumont, E.; Andres, Y.; Le Cloirec, P. Silicone oil: An effective absorbent for the removal of hydrophobic volatile organic compounds. J. Chem. Technol. Biotechnol. 2010, 85, 309–313. [Google Scholar] [CrossRef]

- Lukasiak, J.; Dorosz, A.; Prokopowicz, M.; Rosciszewski, P.; Falkiewicz, B. Biodegradation of Silicones (Organosiloxanes). Biopolym. Online: Biol. Chem. Biotechnol. Appl. 2002, 9, 539–568. [Google Scholar]

- Lehmann, R.G.; Varaprath, S.; Frye, C.L. Degradation of silicone polymers in soil. Environ. Toxicol. Chem. 1994, 13, 1061–1064. [Google Scholar] [CrossRef]

- Lehmann, R.G.; Miller, J.R.; Xu, S.; Singh, U.B.; Reece, C.F. Degradation of Silicone Polymer at Different Soil Moistures. Environ. Sci. Technol. 1998, 32, 1260–1264. [Google Scholar] [CrossRef]

- Xu, S.; Lehmann, R.G.; Miller, J.R.; Chandra, G. Degradation of Polydimethylsiloxanes (Silicones) as Influenced by Clay Minerals. Environ. Sci. Technol. 1998, 32, 1199–1206. [Google Scholar] [CrossRef]

- Lehmann, R.G.; Miller, J.R.; Kozerski, G.E. Degradation of silicone polymer in a field soil under natural conditions. Chemosphere 2000, 41, 743–749. [Google Scholar] [CrossRef]

- Bhisey, M.R. Transparency Market Reseach. Available online: https://www.transparencymarketresearch.com (accessed on 20 February 2019).

- Salleh, K.M.; Hashim, R.; Sulaiman, O.; Hiziroglu, S.; Nadhari, W.N.A.W.; Abd Karim, N.; Jumhuri, N.; Ang, L.Z.P. Evaluation of properties of starch-based adhesives and particleboard manufactured from them. J. Adhes. Sci. Technol. 2015, 29, 319–336. [Google Scholar] [CrossRef]

- Vnucec, D.; Kutnar, A.; Gorsek, A. Soy-based adhesives for wood-bonding—A review. J. Adhes. Sci. Technol. 2017, 31, 910–931. [Google Scholar] [CrossRef]

- Heinrich, L.A. Future opportunities for bio-based adhesives—Advantages beyond renewability. Green Chem. 2019, 21, 1866–1888. [Google Scholar] [CrossRef]

- Plank, J. Applications of Biopolymers in Construction Engineering. Biopolym. Online: Biol. Chem. Biotechnol. Appl. 2005, 10, 29–93. [Google Scholar] [CrossRef]

- Shen, L.; Worrell, E.; Patel, M. Present and future development in plastics from biomass. Biofuels Bioprod. Bioref. 2010, 4, 25–40. [Google Scholar] [CrossRef]

- Kumar, S.; Samal, S.K.; Mohanty, S.; Nayak, S.K. Recent Development of Biobased Epoxy Resins: A Review. Polym.-Plast. Technol. 2018, 57, 133–155. [Google Scholar] [CrossRef]

- Chen, G.-Q. (Ed.) Plastics from Bacteria: Natural Functions and Applications; Springer: New York, NY, USA, 2010; Volume 14. [Google Scholar]

- Chen, G.-Q. (Ed.) Introduction of Bacterial Plastics PHA, PLA, PBS, PE, PTT, and PPP; Springer: Berlin/Heidelberg, Germany, 2010; Volume 14. [Google Scholar]

- Bodo Müller, W.R. Formulating Adhesives and Sealants. Chemistry, Physics and Applications; Vincentz Network: Hanover, Germany, 2010. [Google Scholar]

- Mittal, K.L. Silanes and Other Coupling Agents; Taylor & Francis: Boca Raton, FL, USA, 2009. [Google Scholar]

- Owen, M.J. Why Silicones Behave Funny. Dow Corning Corp. 1981, 11, 288. [Google Scholar]

- Mojsiewicz-Pieńkowska, K.; Jamrógiewicz, M.; Szymkowska, K.; Krenczkowska, D. Direct Human Contact with Siloxanes (Silicones)—Safety or Risk Part 1. Characteristics of Siloxanes (Silicones). Front. Pharmacol. 2016, 7, 132. [Google Scholar] [CrossRef]

- Stoiljkovic, D.; Jovanović, S. Compression, supramolecular organization and free radical polymerization of ethylene gas. Polyolefins J. 2019, 6, 23–41. [Google Scholar] [CrossRef]

- De Buyl, F. Silicone sealants and structural adhesives. Int. J. Adhes. Adhes. 2001, 21, 411–422. [Google Scholar] [CrossRef]

- Müller, B.A.R.; Walter. Formulating Adhesives and Sealants; Vincentz Network GmbH & Co KG: Hanover, Germany, 2010. [Google Scholar]

- Ferdosian, F.; Pan, Z.; Gao, G.; Zhao, B. Bio-Based Adhesives and Evaluation for Wood Composites Application. Polymers 2017, 9, 70. [Google Scholar] [CrossRef]

- Jiménez-Pardo, I.; Van der Ven, L.G.J.; Van Benthem, R.A.T.M.; De With, G.; Esteves, A.C.C. Hydrophilic Self-Replenishing Coatings with Long-Term Water Stability for Anti-Fouling Applications. Coatings 2018, 8, 184. [Google Scholar] [CrossRef]

- Ayyad, A.H. Thermodynamic derivation of the Young–Dupré form equations for the case of two immiscible liquid drops resting on a solid substrate. J. Colloid Interface Sci. 2010, 346, 483–485. [Google Scholar] [CrossRef]

- Rajendran, M.B.A.P. A Review on Electroactive Polymers Development for Aerospace Applications. J. Intell. Mater. Syst. Struct. 2018, 29, 3681–3695. [Google Scholar] [CrossRef]

- Kronberg, B.; Holmberg, K.; Lindman, B. Surface Chemistry of Surfactants and Polymers; Wiley: Hoboken, NJ, USA, 2014. [Google Scholar]

- Bio Based Construction Polymers Market Analysis By Product (Cellulose Acetate, Epoxies, Polyethylene Terephthalate (PET), Polyurethane), By Application (Pipe, Profile, Insulation) And Segment Forecasts To 2024. Available online: http://news.bio-based.eu/grand-view-research-bio-based-construction-polymers-market-analysis-and-segment-forecasts-to-2024/ (accessed on 28 January 2019).

- Market Research Report. Available online: https://www.grandviewresearch.com/press-release/global-bio-based-construction-polymers-market (accessed on 8 May 2019).

- Ahuja, D.; Kaushik, A.; Singh, M. Simultaneous extraction of lignin and cellulose nanofibrils from waste jute bags using one pot pre-treatment. Int. J. Biol. Macromol. 2018, 107, 1294–1301. [Google Scholar] [CrossRef]

- Lindman, B.; Medronho, B.; Alves, L.; Costa, C.; Edlund, H.; Norgren, M. The relevance of structural features of cellulose and its interactions to dissolution, regeneration, gelation and plasticization phenomena. Phys. Chem. Chem. Phys. 2017, 19, 23704–23718. [Google Scholar] [CrossRef] [Green Version]

- Medronho, B.; Lindman, B. Competing forces during cellulose dissolution: From solvents to mechanisms. Curr. Opin. Colloid Interface Sci. 2014, 19, 32–40. [Google Scholar] [CrossRef]

- Medronho, B.; Romano, A.; Miguel, M.G.; Stigsson, L.; Lindman, B. Rationalizing cellulose (in)solubility: reviewing basic physicochemical aspects and role of hydrophobic interactions. Cellulose 2012, 19, 581–587. [Google Scholar] [CrossRef]

- Schuyten, H.A.; Weaver, J.W.; Reid, J.D.; Jurgens, J.F. Trimethylsilylcellulose. J. Am. Chem. Soc. 1948, 70, 1919–1920. [Google Scholar] [CrossRef]

- Bontea, D.; Ioan, C. Synthesis and Characterization of Trimethylsilylcellulose in Solution AU-Aelenei, Nicolae. J. Macromol. Sci. Part A 1998, 35, 1667–1680. [Google Scholar] [CrossRef]

- Carapeto, A.P.; Ferraria, A.M.; Botelho do Rego, A.M. Trimethylsilylcellulose synthesis revisited. Polym. Test. 2017, 58, 236–240. [Google Scholar] [CrossRef]

- Heinze, S.K.T.L.T. Interactions of ionic liquids with polysaccharides. VI. Pure cellulose nanoparticles from trimethylsilyl cellulose synthesized in ionic liquids. J. Polym. Sci. 2008, 46, 4070–4080. [Google Scholar] [CrossRef]

- Kostag, M.; Köhler, S.; Liebert, T.; Heinze, T. Pure Cellulose Nanoparticles from Trimethylsilyl Cellulose. Macromol. Symp. 2010, 294, 96–106. [Google Scholar] [CrossRef]

- Stiubianu, G.; Racles, C.; Cazacu, M.; Simionescu, B.C. Silicone-modified cellulose. Crosslinking of cellulose acetate with poly[dimethyl(methyl-H)siloxane] by Pt-catalyzed dehydrogenative coupling. J. Mater. Sci. 2010, 45, 4141–4150. [Google Scholar] [CrossRef]

- Klemm, D.; Stein, A. Silylated Cellulose Materials in Design of Supramolecular Structures of Ultrathin Cellulose Films. J. Macromol. Sci. Pure 1995, A32, 899–904. [Google Scholar] [CrossRef]

- Robles, E.; Csóka, L.; Labidi, J. Effect of Reaction Conditions on the Surface Modification of Cellulose Nanofibrils with Aminopropyl Triethoxysilane. Coatings 2018, 8, 139. [Google Scholar] [CrossRef]

- Vandenberg, E.T.; Bertilsson, L.; Liedberg, B.; Uvdal, K.; Erlandsson, R.; Elwing, H.; Lundström, I. Structure of 3-aminopropyl triethoxy silane on silicon oxide. J. Colloid Interface Sci. 1991, 147, 103–118. [Google Scholar] [CrossRef]

- Eslah, F.; Jonoobi, M.; Faezipour, M.; Ashori, A. Chemical modification of soybean flour-based adhesives using acetylated cellulose nanocrystals. Polym. Compos. 2018, 39, 3618–3625. [Google Scholar] [CrossRef]

- Khanjanzadeh, H.; Behrooz, R.; Bahramifar, N.; Gindl-Altmutter, W.; Bacher, M.; Edler, M.; Griesser, T. Surface chemical functionalization of cellulose nanocrystals by 3-aminopropyltriethoxysilane. Int. J. Biol. Macromol. 2018, 106, 1288–1296. [Google Scholar] [CrossRef]

- Khanjanzadeh, H.; Behrooz, R.; Bahramifar, N.; Pinkl, S.; Gindl-Altmutter, W. Application of surface chemical functionalized cellulose nanocrystals to improve the performance of UF adhesives used in wood based composites—MDF type. Carbohydr. Polym. 2019, 206, 11–20. [Google Scholar] [CrossRef]

- Syed draman, S.F.; Daik, R.; El-Sheikh, S.; Abdul latif, F. Nanocomposites of cellulose-based adhesive and toluenesulfonic acid-doped polypyrrole prepared via colloidal dispersion. J. Reinf. Plast. Comp. 2013, 32, 1553–1560. [Google Scholar] [CrossRef]

- Ghalib, H.; Abdullah, I.; Daik, R. Synthesis of Polypyrrole Nanoparticles in Natural Rubber-Polystyrene Blend via Emulsion Polymerization. J. Appl. Polym. Sci. 2012, 123, 2115–2121. [Google Scholar] [CrossRef]

- Ates, M.; Karazehira, T.; Sarac, A. Conducting Polymers and their Applications. Curr. Phys. Chem. 2012, 2, 224–240. [Google Scholar] [CrossRef]

- Ceseracciu, L.; Heredia-Guerrero, J.A.; Dante, S.; Athanassiou, A.; Bayer, I.S. Robust and Biodegradable Elastomers Based on Corn Starch and Polydimethylsiloxane (PDMS). Acs Appl. Mater. Interfaces 2015, 7, 3742–3753. [Google Scholar] [CrossRef]

- Sugih, A.K.; Picchioni, F.; Janssen, L.P.B.M.; Heeres, H.J. Synthesis of poly-(epsilon)-caprolactone grafted starch co-polymers by ring-opening polymerisation using silylated starch precursors. Carbohydr. Polym. 2009, 77, 267–275. [Google Scholar] [CrossRef]

- Sugih, A.K.; Picchioni, F.; Janssen, L.P.B.M.; Heeres, H.J. Synthesis of poly-(ε)-caprolactone grafted starch co-polymers by ring-opening polymerisation using silylated starch precursors. Carbohydr. Polym. 2009, 77, 267–275. [Google Scholar] [CrossRef]

- Wei, B.; Sun, B.; Zhang, B.; Long, J.; Chen, L.; Tian, Y. Synthesis, characterization and hydrophobicity of silylated starch nanocrystal. Carbohydr. Polym. 2016, 136, 1203–1208. [Google Scholar] [CrossRef]

- Angellier, H.; Choisnard, L.; Molina-Boisseau, S.; Ozil, P.; Dufresne, A. Optimization of the preparation of aqueous suspensions of waxy maize starch nanocrystals using a response surface methodology. Biomacromolecules 2004, 5, 1545–1551. [Google Scholar] [CrossRef]

- Norgren, M.; Edlund, H. Lignin: Recent advances and emerging applications. Curr. Opin. Colloid Interface Sci. 2014, 19, 409–416. [Google Scholar] [CrossRef]

- Stiubianu, G.; Bele, A.; Tugui, C.; Musteata, V. New dielectric elastomers with improved properties for energy harvesting and actuation. In Advanced Topics in Optoelectronics, Microelectronics, and Nanotechnologies VII; International Society for Optics and Photonics: Bellingham, WA, USA, 2016; Volume 9258, p. 925808. [Google Scholar]

- Feldman, D.; Lacasse, M.; St. J. Manley, R. Polyurethane-based sealants modified by blending with Kraft lignin. J. Appl. Polym. Sci. 1988, 35, 247–257. [Google Scholar] [CrossRef] [Green Version]

- Scarica, C.; Suriano, R.; Levi, M.; Turri, S.; Griffini, G. Lignin Functionalized with Succinic Anhydride as Building Block for Biobased Thermosetting Polyester Coatings. Acs Sustain. Chem. Eng. 2018, 6, 3392–3401. [Google Scholar] [CrossRef]

- Robert, T.; Friebel, S. Itaconic acid—A versatile building block for renewable polyesters with enhanced functionality. Green Chem. 2016, 18, 2922–2934. [Google Scholar] [CrossRef]

- Carlos de Haro, J.; Magagnin, L.; Turri, S.; Griffini, G. Lignin-Based Anticorrosion Coatings for the Protection of Aluminum Surfaces. Acs Sustain. Chem. Eng. 2019, 7, 6213–6222. [Google Scholar] [CrossRef]

- De Haro, J.C.; Allegretti, C.; Smit, A.T.; Turri, S.; D’Arrigo, P.; Griffini, G. Bio-based polyurethane coatings with high biomass content: Tailored properties by lignin selection. ACS Sustain. Chem. Eng. 2019. [Google Scholar] [CrossRef]

- Szubert, K. Synthesis of organofunctional silane from rapeseed oil and its application as a coating material. Cellulose 2018, 25, 6269–6278. [Google Scholar] [CrossRef] [Green Version]

- Mohd Salleh, K.; Hashim, R.; Sulaiman, O.; Hiziroglu, S.; Wan Nadhari, W.N.A.; Abd Karim, N.; Jumhuri, N.; Zuin Ping Ang, L. Evaluation of properties of starch-based adhesives and particleboard manufactured from them. J. Adhes. Sci. Technol. 2015, 29. [Google Scholar] [CrossRef]

- Britz, W.; Hertel, T.W. Impacts of EU biofuels directives on global markets and EU environmental quality: An integrated PE, global CGE analysis. Agric. Ecosyst. Environ. 2011, 142, 102–109. [Google Scholar] [CrossRef]

- Mallégol, J.; Lemaire, J.; Gardette, J.-L. Drier influence on the curing of linseed oil. Prog. Org. Coat. 2000, 39, 107–113. [Google Scholar] [CrossRef]

- Li, Y.; Luo, X.; Hu, S. (Eds.) Polyols and Polyurethanes from Vegetable Oils and Their Derivatives. In Handbook of Bio-based Polyols and Polyurethanes; Springer International Publishing: Cham, Switzerland, 2015; Volume 1, pp. 15–43. [Google Scholar]

- Pizzi, A. Bioadhesives for Wood and Fibres. Rev. Adhes. Adhes. 2013, 1, 88–113. [Google Scholar] [CrossRef]

- Zhang, W.S.; Yu, X.Q.; Li, Y.; Su, Z.Q.; Jandt, K.D.; Wei, G. Protein-mimetic peptide nanofibers: Motif design, self-assembly synthesis, and sequence-specific biomedical applications. Prog. Polym. Sci. 2018, 80, 94–124. [Google Scholar] [CrossRef]

- Rathi, S.; Saka, R.; Domb, A.J.; Khan, W. Protein-based bioadhesives and bioglues. Polym. Adv. Technol. 2019, 30, 217–234. [Google Scholar] [CrossRef]

- Clark, R. Fibrin sealant in wound repair: A systematic survey of the literature. Expert Opin. Investig. Drugs. 2000, 9, 2371–2392. [Google Scholar] [CrossRef]

- Strausberg, R.L.; Link, R.P. Protein-based medical adhesives. Trends Biotechnol. 1990, 8, 53–57. [Google Scholar] [CrossRef]

- Kumar, R.; Choudhary, V.; Mishra, S.; Varma, I.K.; Mattiason, B. Adhesives and plastics based on soy protein products. Ind. Crop. Prod. 2002, 16, 155–172. [Google Scholar] [CrossRef]

- Liu, Y.; Li, K. Chemical Modification of Soy Protein for Wood Adhesives. Macromol. Rapid Commun. 2002, 23, 739–742. [Google Scholar] [CrossRef]

| Samples | Electrical Conductivity (Scm−1) | Thermal Conductivity, k (Wm−1K−1) |

|---|---|---|

| PPy | 5.422 × 10−6 | 0.343 |

| TSA-doped PPy, pH 1 | 8.422 × 10−3 | 0.432 |

| TSA-doped PPy, pH 3 | 1.407 × 10−3 | 0.422 |

| TSA-doped PPy, pH 4 | 9.955 × 10−4 | 0.406 |

| TSA-doped PPy:EC (80:20) | 1.076 × 10−3 | 0.399 |

| TSA-doped PPy:EC (70:30) | 3.751 × 10−5 | 0.371 |

| TSA-doped PPy:EC (50:50) | 3.350 × 10−8 | 0.237 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Magalhães, S.; Alves, L.; Medronho, B.; Fonseca, A.C.; Romano, A.; Coelho, J.F.J.; Norgren, M. Brief Overview on Bio-Based Adhesives and Sealants. Polymers 2019, 11, 1685. https://0-doi-org.brum.beds.ac.uk/10.3390/polym11101685

Magalhães S, Alves L, Medronho B, Fonseca AC, Romano A, Coelho JFJ, Norgren M. Brief Overview on Bio-Based Adhesives and Sealants. Polymers. 2019; 11(10):1685. https://0-doi-org.brum.beds.ac.uk/10.3390/polym11101685

Chicago/Turabian StyleMagalhães, Solange, Luís Alves, Bruno Medronho, Ana C. Fonseca, Anabela Romano, Jorge F.J. Coelho, and Magnus Norgren. 2019. "Brief Overview on Bio-Based Adhesives and Sealants" Polymers 11, no. 10: 1685. https://0-doi-org.brum.beds.ac.uk/10.3390/polym11101685